How Heat Transfer Machines Can Help Streamline Your Production Process

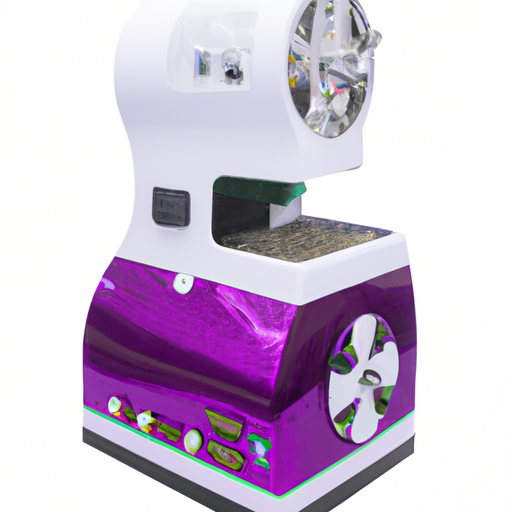

Heat transfer machines are an invaluable tool for streamlining production processes. By using heat transfer technology, businesses can quickly and efficiently produce high-quality products with minimal effort.

Heat transfer machines use a combination of heat and pressure to transfer a design or logo onto a variety of materials. This process is much faster than traditional methods such as screen printing or embroidery, and it produces a much higher quality result. Heat transfer machines can be used to apply designs to t-shirts, hats, bags, and other apparel items. They can also be used to apply designs to hard surfaces such as mugs, plates, and other promotional items.

Heat transfer machines are easy to use and require minimal setup time. They are also highly efficient, allowing businesses to produce large quantities of products in a short amount of time. This makes them ideal for businesses that need to produce a large number of products quickly and efficiently.

Heat transfer machines are also cost-effective. They require minimal maintenance and can be used for a variety of different projects. This makes them a great investment for businesses that need to produce a large number of products in a short amount of time.

Overall, heat transfer machines are an invaluable tool for streamlining production processes. They are easy to use, highly efficient, and cost-effective. By using heat transfer technology, businesses can quickly and efficiently produce high-quality products with minimal effort.

The Benefits of Investing in a High-Quality Heat Transfer Machine

Investing in a high-quality heat transfer machine can provide a number of benefits for businesses and individuals alike. Heat transfer machines are used to transfer images, text, and designs onto a variety of materials, including fabric, paper, and plastic. This process is often used to create custom apparel, promotional items, and other products.

The first benefit of investing in a high-quality heat transfer machine is the ability to produce professional-looking results. Heat transfer machines are designed to provide precise and consistent results, allowing users to create products with a professional finish. This is especially beneficial for businesses that need to produce high-quality products in a short amount of time.

Another benefit of investing in a high-quality heat transfer machine is the cost savings associated with the process. Heat transfer machines are relatively inexpensive to purchase and operate, making them an ideal choice for businesses that need to produce large quantities of products. Additionally, the cost of materials used in the process is typically lower than other methods of printing.

Finally, investing in a high-quality heat transfer machine can help businesses save time. Heat transfer machines are designed to be user-friendly and efficient, allowing users to quickly and easily produce products. This can help businesses save time and money by reducing the amount of time spent on production.

Overall, investing in a high-quality heat transfer machine can provide a number of benefits for businesses and individuals alike. Heat transfer machines are designed to provide precise and consistent results, allowing users to create products with a professional finish. Additionally, the cost savings associated with the process and the time savings associated with the process make heat transfer machines an ideal choice for businesses that need to produce large quantities of products.

Tips for Maintaining Your Heat Transfer Machine for Optimal Performance

1. Regularly Clean the Machine: To ensure optimal performance, it is important to regularly clean your heat transfer machine. This includes wiping down the exterior of the machine, as well as cleaning the interior components such as the rollers and heating elements.

2. Check the Temperature Settings: Make sure to regularly check the temperature settings on your heat transfer machine to ensure that they are set correctly. This will help to ensure that your heat transfer prints are of the highest quality.

3. Inspect the Rollers: Inspect the rollers of your heat transfer machine on a regular basis to ensure that they are in good condition. If the rollers are worn or damaged, they should be replaced to ensure optimal performance.

4. Check the Pressure Settings: Make sure to regularly check the pressure settings on your heat transfer machine to ensure that they are set correctly. This will help to ensure that your heat transfer prints are of the highest quality.

5. Replace Worn Parts: If any parts of your heat transfer machine are worn or damaged, they should be replaced as soon as possible. This will help to ensure that your machine is running at its optimal performance level.

6. Perform Regular Maintenance: It is important to perform regular maintenance on your heat transfer machine to ensure that it is running at its best. This includes checking the temperature and pressure settings, inspecting the rollers, and replacing any worn or damaged parts.