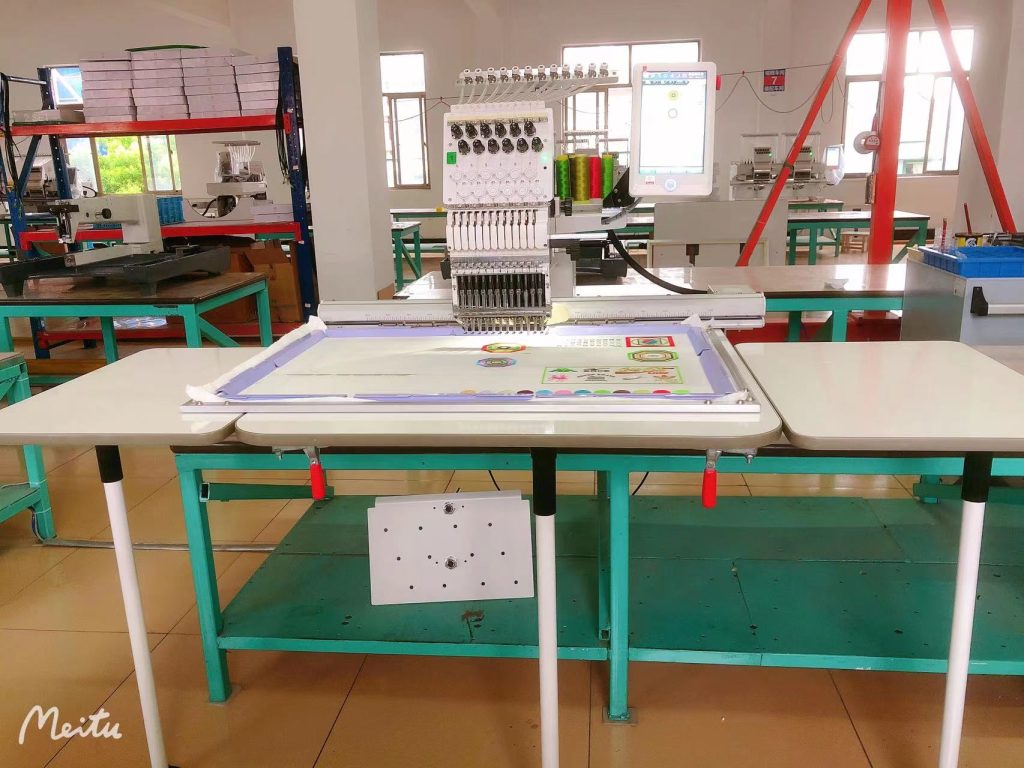

- First, enter the data into the machine, adjust the starting position, then make sure the position is set properly. If it is suitable, go straight back to the origin and click on “direct embroidery” to start.

- After the machine is running, you need to rewind the empty cores underneath in time for later use. After you have run out of thread on two or three cores in a row, you can pause the machine and replace all the cores when you reach the bottom of the embroidery. Then re-wind the cores, and so on.

- Also pay attention to whether the coloured threads are about to run out. If you are close to running out of thread, connect it from the source, pull the new thread out and re-thread it. If you do not find that, you need to rethread the thread a little bit to hang it, it is very troublesome and you cannot make a mistake. If the wrong winding, the machine will often stop automatically.

- The plywood is also very tiring. First you need to lay a layer of lining paper on the frame and fix it. Then the cloth is laid on again and fixed in place. This is done at the same time as entering the data. However, the data is only entered once, and this is done after each embroidery of the pattern in the frame, and the splint is fixed again.

- Wipe the thread oil once a day and the machine oil twice a day to help the machine run better so that it is less to break and can improve efficiency.

monogram embroidery machine hoops,monogram embroidery machine per day,monogram embroidery machine toward the end of the stitch,monogram embroidery machine xerox,k&k embroidery,The tips for using monogram embroidery machine factory wholesalers,monogram embroidery machine in nigeria,monogram embroidery machine despite definition,monogram embroidery machine 3 in 1,embroidery machine for logo.The tips for using monogram embroidery machine factory wholesalers